Technologies

Technologies

Growth and innovation

Future-oriented technology.

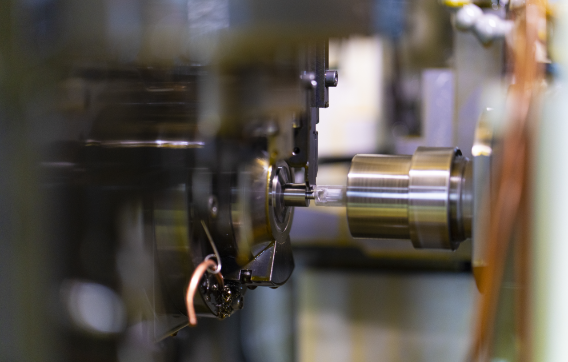

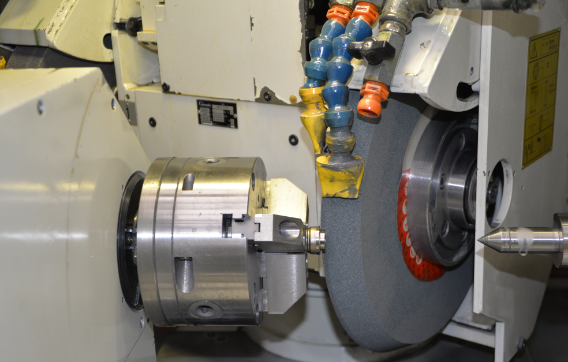

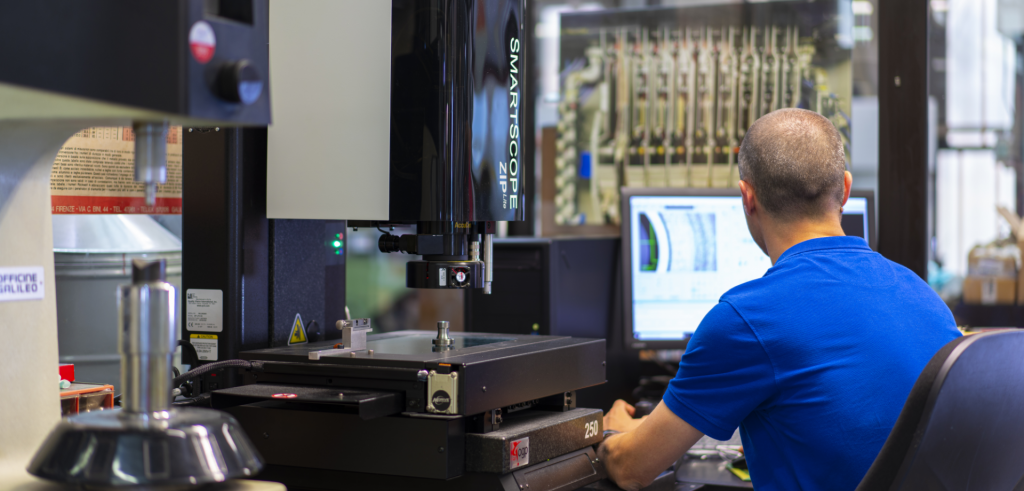

MICRON consolidated its growth over time by innovating, improving and increasing its production department with new high tech CNC machines with high technological content, making its company slogan “Future-oriented technology”. Micron implemented its software systems with a CAD / CAM drawing integrated system suitable for making it easier to transfer information from the budgeting phase to the production. The company is also able to carry out in-house or with the help of qualified suppliers the operations for the realization of the details as per technical drawing: surface treatments, heat treatments, galvanic treatments, lapping, painting and laser marking.